-

Zirconium oxide structures

: Zirconium oxide structuresProstheses made of zirconium dioxide, perfectly matching the color and shape of teeth.

Metal-free constructions

Prostheses with ceramic-coated surfaces are among the most aesthetic and realistic-looking. The production of such prostheses usually consists of two stages:

1. Formation of the framework, which provides strength to the prosthesis.

2. Application of 3 to 18 layers of ceramic to the surface of the framework, making the prosthesis visually indistinguishable from a natural tooth.

The framework can be made in various ways from cobalt-chromium alloys (metallic), or it can be metal-free. There are several materials that can substitute metal in the creation of the framework. Mostly, this is pressed ceramic or zirconium dioxide.

You can learn more about the production of zirconium dioxide frameworks on the page of the relevant department.

Prostheses made of zirconium dioxide, perfectly matching the color and shape of teeth.

One of the main methods for creating the framework is filling the framework mold with Ivoclar IPS e.max Press ceramic, followed by baking in an Ivoclar Programat EP 3000 or Vita Vacuumat 600 MP pressing furnace. Creating the mold for filling requires the preliminary creation of a wax model of the framework.

This model can be created manually by a technician, or it can be milled in our digital milling center on the CORiTEC 150i PRO. Milling a wax model is much more precise and faster than the alternative method.

To speed up the production of a ceramic framework, the process of mold-making and ceramic pressing can be avoided.

Our milling center allows milling ceramic frameworks from pre-prepared IPS e.max CAD blocks.

Once the framework is ready, the stage of multi-layer ceramic application on its surface begins. This helps to achieve natural color transitions and translucency at the cutting edge of the final prosthesis, resembling natural teeth. The exception is “full anatomy”.

In this case, to reduce cost and speed up the prosthesis production process, no additional ceramic layers are applied to the ceramic framework. The prosthesis is, therefore, of a uniform color.

Types of work

USD

30511

Zirconia crown, full-contour

$140

40313

Intermediate part of the bridge (E.MAX full contour)

$135

120404

E.MAX crown, screw-retained, full contour, without TiBase

$170

120415

Intermediate bridge part on implants (E.MAX full contour)

$135

When covering the framework with IPS e.max Ceram ceramic, each layer is successively baked in the Programat P310/G2 or Vita Vacuumat 30, which raise and lower the temperature strictly according to a verified formula.

Types of work

USD

40314

Intermediate part of the bridge (E.MAX with ceramic layering)

$145

120404V

E.MAX crown, screw-retained, with ceramic layering, without TiBase

$185

120415V

Intermediate bridge part on implants

(E.MAX with ceramic layering)

$145

For metal-free ceramic work, it is possible to add an artificial gum – “pink aesthetics”. The pink aesthetics are created by the technician from IPS e.max Ceram Gingiva ceramics simultaneously with the application of the surface layers of ceramics.

120413

Pink aesthetics (1 unit)

$35

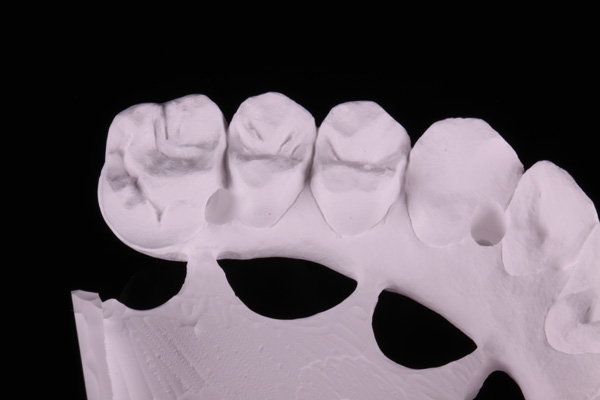

We accept intraoral scans, dental impressions, plaster models, and STL files. The STL file implies a ready-to-send model that does not require modeling by our technicians.

The production time depends on the type of model provided. An STL file is the fastest option.

All other impressions require modeling before production. The plaster model and dental impression, unlike the intraoral scan, need to be digitized. The dental impression will need to be cast in plaster beforehand.

Typically, IPS e.max work takes up to 7 days.

As part of the above-mentioned technologies, we also offer the production of veneers and “full anatomy” occlusal inlays from IPS e.max.

Technicians working in this department