Our advantages

production time – from 1 day

Our clients receive one of the most operational productions on the market

Free shipping to anywhere in the Czech Republic

We provide free delivery of orders to all customers of the laboratory

we produce structures of any complexity

Including in case of malocclusion or to simulate teeth in conditions of acute atrophy of the jaw bone

-

Zirconium oxide structures

: Zirconium oxide structuresProstheses made of zirconium dioxide, perfectly matching the color and shape of teeth.

-

Metal-free constructions

: Metal-free constructionsIdeal aesthetics, stability, biocompatibility, and durability of fixed dental prostheses.

-

Metal-ceramic constructions

: Metal-ceramic constructionsMultilayer ceramic coating on a metal cast or milled frame is a time-tested combination.

-

Removable dentures

: Removable denturesFabrication of removable dental structures for restoring the function and aesthetics of missing teeth.

-

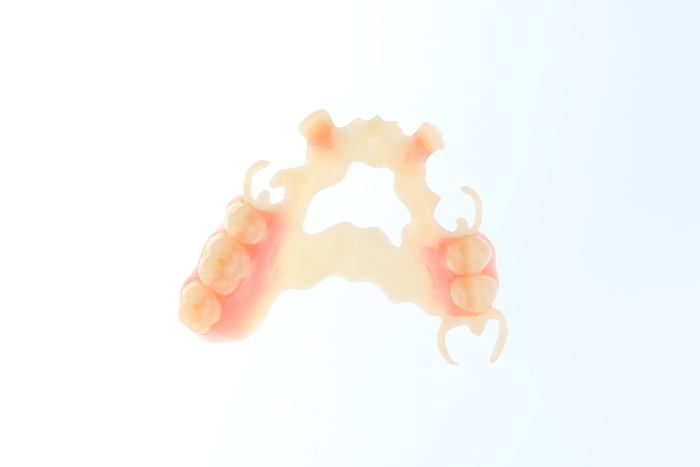

Clasp dentures

: Clasp denturesStructures with a metal framework for partial tooth replacement provide comfort and reliability.

-

Temporary constructions

: Temporary constructionsTemporary dentures restore function and aesthetics until final prosthetics.

-

Implant-supported prosthetics

: Implant-supported prostheticsFixing dental restorations on titanium roots for stability and durability of prostheses.

-

Hybrid dentures

: Hybrid denturesModern solutions for dental restoration: a combination of implants and removable structures.

-

Orthodontics

: OrthodonticsManufacturing orthodontic appliances for bite correction and teeth alignment.

-

3D-modeling

: 3D-modelingDevelopment of digital models of prosthetics, templates for implantation and orthodontic structures.

-

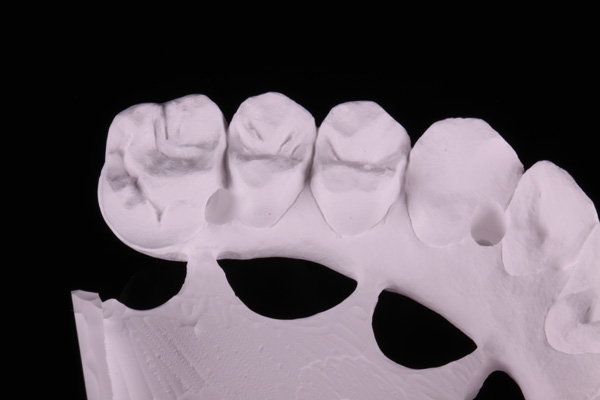

3D-printing

: 3D-printingCreate prototypes and models using 3D printing for detailed and precise products.

-

Ugin Dentaire Ducatron Quattro

The centrifugal induction casting machine is our main tool for working with cobalt-chromium alloys. The machine’s inductor melts the metal, creating chaotic oscillations in the alloy at the molecular level. The heating is very localized. The inductor coil is water-cooled. The molten metal flows into the mold under the influence of centrifugal force generated by the rapid rotation of the structure holding the crucible and mold.